MT3 — Vic Secret Cold IPA (Reluctant Lager Edition)

This brew sits firmly in the Lab Reports corner of Brewology: a one-off, community-driven experiment rather than a polished “house recipe”. The catalyst is Motler-Testers, a tasting-and-brewing programme run by Alice at MotlerHops, where a single hop variety is put under the spotlight through a shared recipe, brewed by many hands, then compared and discussed together.

The premise is simple (and brilliant): the community helps steer the choice, a common recipe is provided, and everyone brews to the same brief — so differences in process, water, fermentation choices, and hop handling become part of the learning. The goal isn’t to crown a “winner”, but to tease out what the hop really does when you give it a clear stage and a consistent baseline.

For this edition, the selected hop was Vic Secret, and the style was Cold IPA — deliberately designed as a clean, bright canvas that lets the hop do most of the talking. The kit and instructions (provided by Alice) emphasise exactly that: a neutral, refreshing base, a hopstand, and a substantial dry hop, all built to “put Vic Secret at centre stage”.

Confession time: I didn’t vote for the style, and I approached the idea of a Cold IPA with some reluctance. That hesitation is mostly yeast-shaped — lagers (pilsners, lagers, and their crisp cousins) aren’t usually where my brewing heart lives and I might have been driven away from the style due to personal experiments with mass market Pils beverages here in Belgium (yes, you with the red label). Still, the whole point of a community experiment is to brew outside your comfort zone, compare notes honestly, and learn something you wouldn’t have chased on your own. So: deep breath…

Vic Secret, Cold IPA, and me — here we are.

Quick specs overview

- Style target: Cold IPA (Vic Secret showcase)

- Batch size: homebrew

- ABV target: 7% (my tweak vs the original 6%)

- OG / FG targets: ~1.064 / ~1.012

- Hop: Vic Secret (single-hop focus)

- Yeast: LalBrew NovaLager

- Fermentation: 16°C → ~18°C

- Mash: 60 min @ 65°C + 10 min @ 72°C

- Boil: 75 min

- Water: SO₄²⁻/Cl⁻ ratio of 2

Results of the votes

The hop

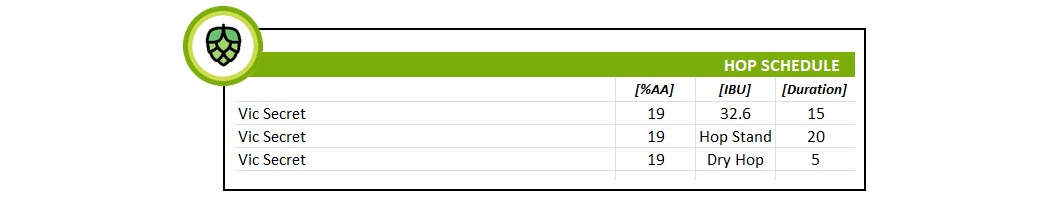

Vic Secret™ is an Australian hop developed by Hop Products Australia (HPA), celebrated for its “big pineapple” tropical punch backed by a firm, resinous pine edge. HPA’s technical data frames it as a high-impact late-hop: the variety is best accessed through whirlpool and dry hopping (late-kettle use tends to lean more earthy), with a headline flavour profile of pineapple, pine, and herbs. Analytically it’s a high-alpha cultivar (~18.4–21.6% AA) with substantial essential oils (~2.1–2.9 mL/100 g), which helps explain why it can read as both “clean” and intense when used for aroma-forward additions.

Our 2025 crop lot supplied by Alice has a content of 19% AA.

| Alpha acids [%] | 18.4 - 21.6 |

| Beta acids [%] | 6.3 - 7.8 |

| Cohumulone [% of aa] | 51.0 - 56.0 |

| Total oils [mL/100g] | 2.1 - 2.9 |

| Myrcene [% of total oil] | 31.0 - 46.0 |

| Humulene [% of total oil] | 9.4 - 12.2 |

| Caryophyllene [% of total oil] | 9.8 - 10.7 |

| Linalool [% of total oil] | 0.1 - 0.7 |

| Selinene [% of total oil] | 3.8 - 4.2 |

| Farnesene [% of total oil] | - |

Cold IPA

Cold IPA is one of those modern “hybrid” ideas that brewers understand instantly, even if formal style bodies don’t always name it the same way: the goal is IPA-level hop expression delivered over a very crisp, lager-leaning base. In competition-style terms, it’s commonly treated as overlapping with (or adjacent to) India Pale Lager (IPL). The Brewers Association (BA) includes American-Style India Pale Lager in its Beer Style Guidelines: pale colour, low-to-medium malt, medium-to-high hop aroma/flavour, medium-to-high (not harsh) bitterness, very low esters, and explicitly no DMS/diacetyl — with typical ranges around 5.6–7.9% ABV and 30–70 IBU. The North American Brewers Association goes further and explicitly groups the concept as “India Pale Lager or Cold IPA”, describing a bright, haze-free, highly hop-aromatic beer (citrus/tropical/resinous notes), dry and well attenuated, typically 6.0–7.5% ABV and 30–80 IBU (reference).

Meanwhile, the BJCP doesn’t define Cold IPA as a standalone style in its core guidelines; instead it suggests entering it as 34B Mixed-Style Beer (conceptually American IPA + American Lager), which is a neat indicator of how the style is still being “filed” by judges rather than canonised.

Could we go further and assimilate this style to an extreme West-coast IPA? We’ll learn more at the end of this experiment and MT3 edition.

The recipe and what I changed

Alice’s Motler-Testers kit is intentionally minimalist: 23 L, a target of ~6% ABV (DI 1.053, DF 1.008), and a very clean fermentables bill (4.5 kg Pilsen malt + 1.0 kg flaked rice). The idea is obvious and I fully buy into it: keep the base neutral, crisp, and refreshing so Vic Secret has nowhere to hide. I kept that philosophy, but I made a few adjustments to better fit my palate and to stress-test the concept in a slightly different direction.

Pushed the strength a tad

Belgian reflex, probably. I wanted a bit more “Oomph”. The kit’s 6% is perfectly sensible, but when I think IPA, my brain tends to expect a bit more structure and warmth. So I nudged the targets towards ~7% ABV. The obvious risk is that extra gravity can add malt weight and blur the “cold” crispness. Everything else I changed is basically me trying to add ABV without adding heaviness.

Clean base

I kept the base as clean as possible: Weyermann Extra Pale as the backbone to stay aligned with the kit’s intent (neutral canvas) as much as possible. This is very much a “get out of the way” base malt choice: pale, clean, and happy to carry hop-forward beers. It also pairs well with what comes next: when you lean harder into adjuncts, you want a base malt that will comfortably convert the mash and still produce a crisp wort.

Increased flaked rice amount

The original kit already uses rice to lighten the body (about 1 kg rice in 5.5 kg total fermentables, so ~18%). I pushed the rice up to 25% of the grist. My reasoning was simple:

- Crisper, drier impression: rice helps strip back malt fullness and keeps the finish snappy.

- Sharper hop delivery: a leaner base tends to make hop aroma feel more “in focus” (less muffled by malt).

- Keeps the 7% target drinkable: if I’m adding strength, I want it to drink bright, not “bigger”.

So yes, more rice — but with a plan to avoid the beer becoming thin.

Two small “insurance” malts

Here’s where my “Belgian genes” probably show up again: I like a beer that’s crisp, but not hollow. With 25% rice and a very pale base malt, it’s easy to overdo the dryness and end up with something that feels watery once the hop haze settles. So I added two small supporting players:

- 2.5% Weyermann Barke Vienna: not enough to turn this into a Vienna anything, but enough to add a hint of malt roundness so the beer doesn’t feel skeletal behind the hops.

- 2.5% Weyermann CaraPils: my practical foam/body safety net. With a hop-forward beer (and a rice-heavy grist), I want head retention and a little mid-palate support without drifting into caramel sweetness.

The point of both additions is structure, not flavour dominance. I still wanted the beer to read as Cold IPA first, hop showcase always.

Yeast choice

The kit proposes two yeast routes: LalBrew NovaLager or Fermentis SH-45. I went with NovaLager.

Why? Because for this experiment I wanted the fermentation profile to stay clean and IPA-friendly, and the kit’s own fermentation guidance places NovaLager in a sensible range for this kind of “lager yeast, warmer fermentation” approach (it explicitly suggests 16–20°C for NovaLager). I’ll start at 16°C and let it rise. Also, that is a new yeast for me, all the better for this experiment!

In other words: I’m not trying to brew a classic lager here — I’m trying to get that crisp, low-ester, high-attenuation feel that supports modern hopping, without turning the brewday into a months-long lagering commitment. Can’t wait to discuss the results at the end of this MT3 edition!

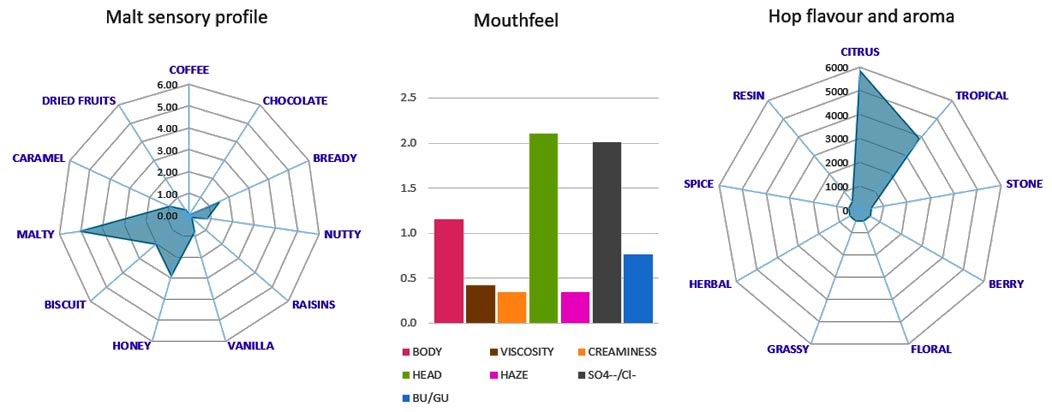

The targeted profile

Given the discussed considerations, the malt, mouthfeel and hop profile should be close to what the next scheme is showing. In terms of flavours, pineapple and tropical flavours should dominate the game here. The predicted profiles and mouthfeel expectations are shown in the scheme below.

Malt Profile (left), mouthfeel (middle) and hop Profile (right)

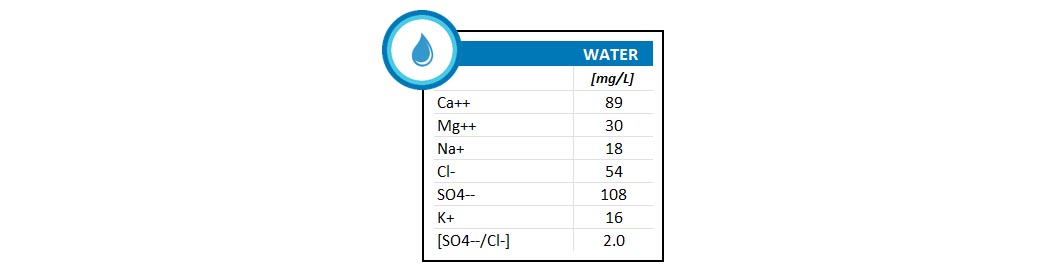

Water profile

I kept the water adjustments minimal and very goal-driven. For this Cold IPA I wanted a clear sulphate-forward profile, so I aimed for a SO₄²⁻/Cl⁻ ratio of ~2, with ~50 mg/L chloride and ~100 mg/L sulphate. That balance should push the beer towards a drier, snappier bitterness and a brighter hop expression, without stripping all roundness from the palate.

My starting water is already quite hard, so the main constraint was to shape the sulphate/chloride balance without pushing calcium even higher than it already wanted to be. That’s why I used KCl and MgSO₄ as my primary adjustment salts: KCl lets me raise chloride while keeping the calcium budget under control, and MgSO₄ lifts sulphate while adding only a modest amount of magnesium (handy in small doses for yeast performance). I still aimed for ~90 mg/L Ca²⁺ overall to support clarity and strong hot/cold break formation — enough to help protein precipitation, but not so much that the beer drifts into a “mineral-forward” profile instead of staying crisp.

Water profile

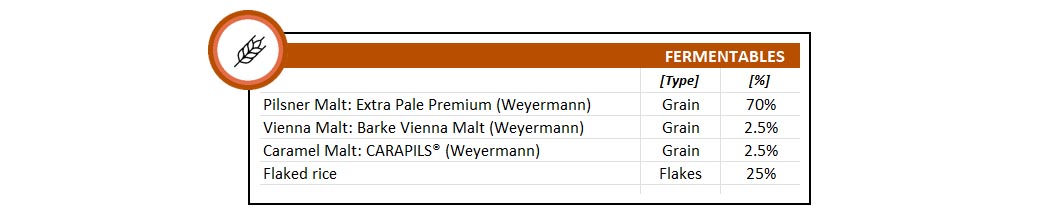

The grist

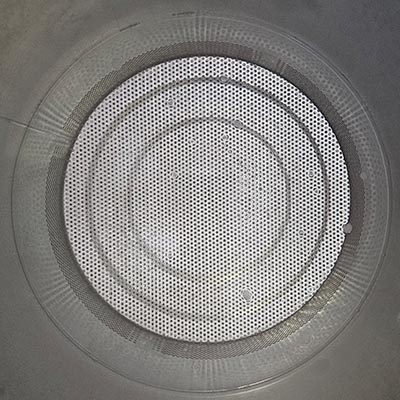

The next table presents the final grist. Note the presence of a little amount of rice husks in the flaked rice fermentable. This is to help the recirculation and sparging sequences.

The final grist

The grains before milling

Crushed Malt

Rice and their husks, literally

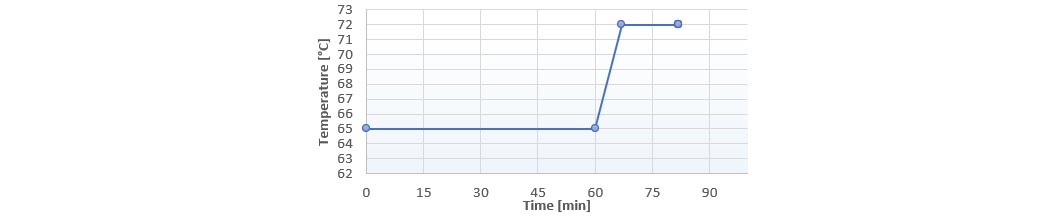

Mash schedule and kettle timeline

For this brew I kept things deliberately straightforward: one mash profile designed to give me a dry, crisp finish, but still with just enough structure to avoid the beer feeling watery (especially with 25% rice in the grist).

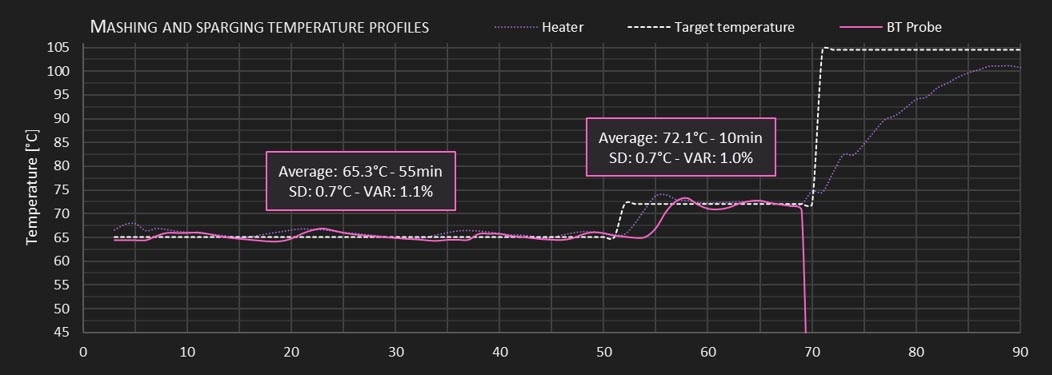

I mashed in for 60 minutes at 65°C. According to the original recipe it favours a more fermentable wort, supporting the whole Cold IPA idea (bright, snappy, high drinkability), and it also helps counterbalance the extra ABV target. After that I raised to 72°C for 10 minutes. I treat this as a short “polish” step: a bit of dextrin support, a touch of mouthfeel insurance, and a neat way to help conversion finish cleanly before runoff.

Once conversion was done, I sparged at 78°C, collected the wort, and straight into the kettle.

The mash regime

The boil was 75 minutes. Similarly to the original recipe, I kept the hop character firmly in the late additions, as intended for a hop showcase: no early bittering charge, no unnecessary background noise. The first hop addition took place at 15 minutes before flame-out. This is the only “boil” hop charge in the whole process, aimed at setting the bitterness foundation (approx. 30 IBU) without wasting precious Vic Secret character on long-boil volatility. At the same time I added my kettle helpers: yeast nutrient + DAP + Irish moss (one combined “utilities” moment, because I like my brewday to stay tidy and repeatable).

Vic Secret, for hopstand and immediately back under vacuum for future dry hopping

Flame-out / hop stand: after the boil I dropped the wort to 80°C and held a 20-minute hop stand. This is where I wanted the aromatic extraction: enough heat to pull oils efficiently, but cooler than a rolling boil to preserve the bright tropical profile rather than cooking it into something heavier. And trust me, the flavours here were simply divine!

After the hop stand I went for rapid cooling, then transferred to the fermenter. Yeast went in, and my RAPT pill was the final “infrastructure” step before closing everything up — because for an experiment like this I want tight monitoring, not vague guesses.

Hop schedule

Fermentation plan

Primary fermentation started at 16°C, with the plan to let it rise gradually to around 18°C. That temperature window seems to be a good compromise for this style: clean lager-leaning profile, but not so cold that fermentation drags or becomes temperamental. I’ll keep a close eye on it and adjust as needed based on actual behaviour rather than sticking stubbornly to a number.

Images and facts from the brewday

- Mash pH 5.54, sparge pH 5.8

- Boil pH 5.58, end boil pH 5.28

- 1.26 g/L hops at boil

- 3.36 g/L hops at hop stand

- 6.72 g/L hops at dry hop

- 89% conversion efficiency

- 92% extraction efficiency

- 82% total efficiency

- OG 1.064, predicted FG 1.012, expected ABV 7.1%

- Primary fermentation temperature 16°C

Please find below a series of images from the brewday.

Mashing water

Mashing water pH

Vic Secret hops

Mashing (t0)

Mashing (t10)

Mashing (t60)

Mashing temperatures

After sparging

Boiling step

Cooling step

Fermenter and Pill

OG (1.064, averaged)

Fermentation is now ongoing

Currently bubbling at 15.8°C, stay tuned for the next steps: dry hopping, bottling / kegging and finally tasting! 🙂

Recent Comments