Abstract

Hop-derived flavour is fragile and is won or lost at three moments: harvest, storage, and in the finished beer. This review distils agronomic and brewing research into practical guidance for brewers, with an emphasis on the two variables that matter most: oxygen and temperature. At harvest, rapid handling prevents “mowburn”; gentle drying (≈40 °C) preserves a greater share of essential oils than conventional hotter kilning. During storage, cold, oxygen-free conditions (vacuum or inert gas at ≤4 °C, ideally frozen) markedly slow losses of α-acids and aroma; pellets outperform cones only when oxygen is excluded, whereas cones can weather early aerobic exposure slightly better. We explain HSI as a quick health check and highlight oil behaviour: hydrocarbons such as myrcene collapse fastest, while oxygenated terpenes (e.g., linalool/geraniol) are comparatively persistent. In beer, cold chain dominates aroma retention, and packaging choice matters—cans typically protect hop volatiles better than crown-capped bottles due to liner sorption. A “survivable compounds” approach is advocated: bank durable, soluble terpenes via late hot-side and active-fermentation dry hop, then use post-fermentation additions as a finishing polish. Clear SOPs—small packs, vacuum sealing, minimal opens, cold storage, HSI/oil tracking—translate the science into everyday decisions that keep hop character lively from bine to glass.

1. Harvesting & immediate post-harvest handling

1.1 Harvest timing (maturity) and downstream flavour stability

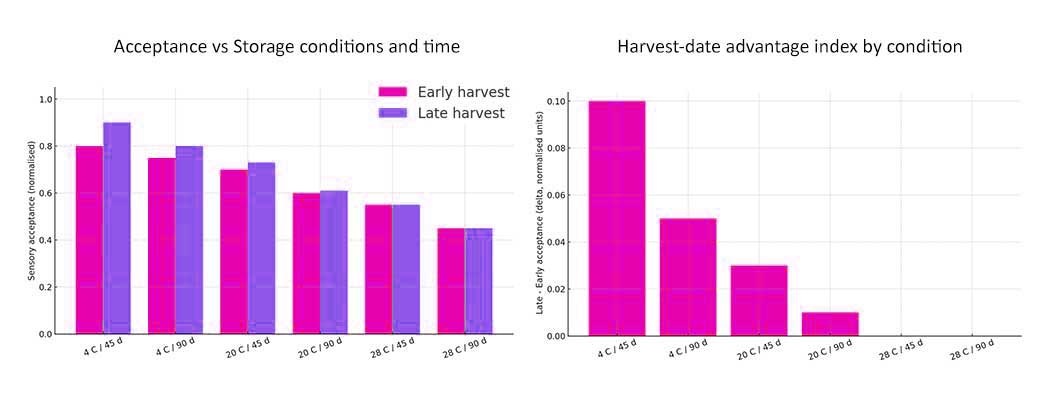

In a controlled programme on Hallertauer Mittelfrüh from four Hallertau farms, five harvest dates (20 August to 13 September, six-day intervals) were evaluated; stability testing compared beers brewed with an early (date 2) versus very late (date 5) pick, then stored 4, 20 or 28 °C and tasted after 45 and 90 days by a trained panel. The late-harvest beers showed slightly better flavour stability and acceptance at 45 days, but the advantage diminished by 90 days and was mostly evident only under cold storage; warmth (especially 28 °C) overwhelmed any harvest-date benefit, depressing flavour and aroma scores across the board. Bitterness quality tracked better with late-picked hops at 4 °C, while bitterness intensity was largely stable—likely a perceptual effect mediated by changing hop aroma. Variation between farms sometimes matched the harvest-date effect, underscoring that cold-chain after packaging matters far more than picking a week later.

1.2 Don’t let fresh cones “mowburn”

Freshly picked cones respire intensely. When heaped in bins, interior layers quickly hit 39–49 °C and 100% RH within hours—classic “mowburn” conditions that accelerate loss of desirable substances and oxidative damage. While this is not the objective of this article, practical guidance from the literature and earlier agronomic recommendations is blunt: limit wet-hop hold time to ~2 hours before drying or spreading thin for active ventilation.

1.3 Drying: temperature sets the oil budget

Conventional hop kilns run ~55–60 °C for 10–12 h to 8–11% moisture. Gentle kilning at ~40 °C retained ~90% of flavour substances with oil composition broadly maintained, whereas 55 °C drying cut total oils ~36% (Saaz) and ~43% (Harmonie) vs fresh in one controlled study. (Ratios of individual oil components changed little, hence similar sensory “shape” but a quieter aroma.) Target 9–10% moisture to avoid cone shatter below ~7%.

1.4 Alternative gentle dehydration routes

A recent comparison (Cascade) of freeze-drying, hot-stove, and ventilated room temperature (VRT) drying found:

- The hop storage index (see paragraph 2.1) increased with all techniques, especially in freeze- and hot-stove treatments.

- VRT (5 days at ~25 °C with active airflow) preserved more polyphenols and maintained an essential-oil profile comparable to other methods; freeze-drying performed best chemically but is cost-intensive.

Overall, VRT emerges as a viable, lower-energy option for small producers, with good aroma retention.

2 Storage prior to brewing

2.1 What HSI actually measures, and how to use it

The Hop Storage Index (HSI) is the ratio of absorbance at 275 nm to 325 nm in an alkaline iso-octane extract; it tracks oxidation of hop resins and correlates with loss of alpha-acids. Use it to triage and rotate lots (lower is fresher). It rises as α- and β-acids oxidise. A practical relation to overall resin loss reported is:

% (α+β) lost ≈ 102–115 × log(HSI / 0.247–0.254) (slope varies by crop year).

Fresh hops sit around HSI ≈ 0.25. Track ΔHSI rather than absolute values across lots and time.

2.2 Resins: temperature and oxygen are the big levers

A year-long pellet study showed that cold, anaerobic storage left alpha-/beta-acids essentially unchanged (within method repeatability), whereas 20 °C in air caused ~60–80% losses of both alpha- and beta-acids and depressed polyphenols. In the same work, 20–25% alpha-acid loss was seen after 12 months at 20 °C anaerobic, with beta-acids comparatively stable.

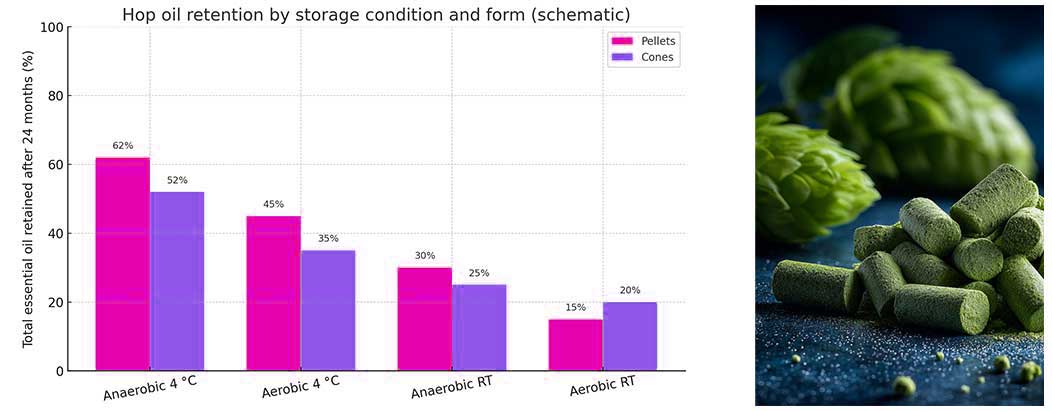

A two-year cones-and-pellets study across six varieties confirms the pattern: anaerobic at 4 °C performs best for alpha-/beta-acids and HSI, while aerobic room temperature is worst (63–99% alpha-acid losses depending on variety). Overall, pellets outperform cones if oxygen is excluded. See the graph below.

2.3 Essential oils: losses, composition, and form effects

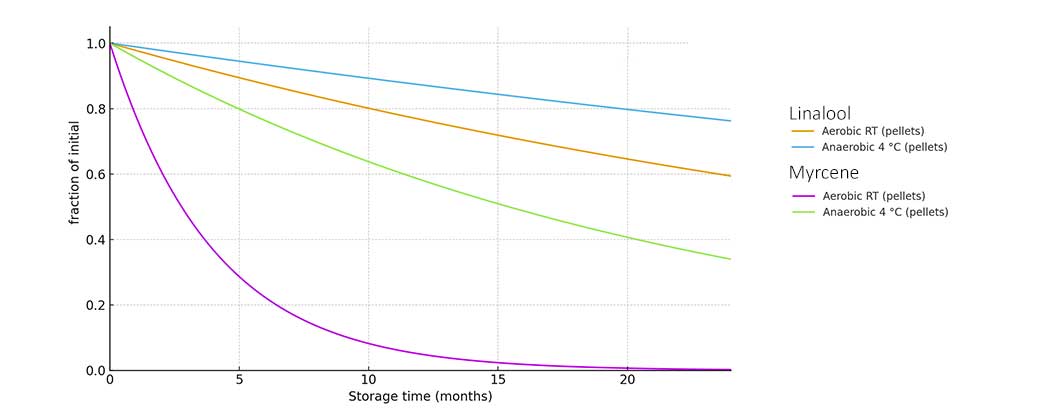

An oil-focused 24-month study found the largest oil losses under aerobic room temperature. For example, Celeia cones lost ~74% of oil at room temperature in air. Pellets were especially vulnerable to oxygen exposure (nearly 85% oil loss in air at room temperature), but did well anaerobically at 4 °C. Relative composition stayed more stable than totals in several datasets; myrcene consistently dropped fastest, making it a useful “red-flag” indicator in COAs.

Pellets vs cones, in short: pellets concentrate lupulin and are easier to keep cold and oxygen-free, so they win under tight O₂ control; when oxygen is present, intact cones can outlast pellets because cracked glands expose oils in pellets to evaporation/oxidation.

2.4 Cones vs pellets: it depends on oxygen

Over multi-month storage across varieties and conditions:

- Anaerobic & cold is best for both forms.

- Under aerobic conditions, pellets (with cracked lupulin) lost oil (e.g., myrcene) faster than cones early on; cones proved more stable when oxygen was present.

- Under anaerobic (oxygen-excluded) storage, pellets outperformed cones.

- Myrcene declines across all conditions and is a reliable indicator of age/abuse; its oxidation/hydration yields linalool and related oxygenates over time.

2.5 Chemical trajectories you should expect

- Monoterpene hydrocarbons (e.g., myrcene) fall steeply, especially warm/aerobic.

- Linalool and geraniol can rise initially via biotransformations from myrcene/geraniol pools, then plateau/decline.

- β-caryophyllene → caryophyllene oxide tracks oxidative load in lupulin.

- Variety and form matter; set variety-specific shelf-life expectations rather than a one-size “best-by”.

2.6 Survivable compounds: brew for what endures

“Survivable compounds” is a brewer-facing framework that prioritises hop volatiles most likely to carry through whirlpool, fermentation, and maturation into packaged beer. In practice, it nudges schedules towards late hot-side (whirlpool/knock-out) and active-fermentation dry hop to bank the more soluble, oxygenated monoterpenes (e.g., linalool, geraniol, β-citronellol), while treating late cold-side as a finishing polish rather than the sole source of aroma. The aim isn’t just bigger aroma on brew day—it’s aroma that lasts on shelf.

Across ageing studies, monoterpene hydrocarbons (e.g., myrcene) deplete fastest whereas monoterpene alcohols are comparatively persistent (some even rise initially via transformations). That’s why “survivables” skew your budget toward chemistry that’s more likely to be in the glass weeks later. Keep the cold chain tight after packaging to preserve the balance you built.

Please have a look at the Yakima Chief Hops website for more information, they have done an amazing work (here).

2.7 All things considered

For homebrewers, the single biggest determinant of hop freshness in storage is the combo of oxygen and temperature: keep oxygen out and temperature down, or you’ll forfeit most of the aroma you paid for. A two-year study across six varieties (cones and T90 pellets) tested four regimes—anaerobic vs aerobic and 4 °C vs room temperature—and the pattern is stark: aerobic room-temperature storage produced the heaviest oil losses (pellets ≥ 70% in all cases, often ~85–91%; cones typically ~72–85%), while the best case, anaerobic at 4 °C, still cost ~31–47% for pellets and ~36–63% for cones depending on variety.

Pellets are especially sensitive to oxygen — their myrcene was “almost all gone” within the first 4 months when stored warm in air, whereas oxygen-free storage kept early losses much lower (temperature then becomes the separator after ~9–14 months). Cones, by contrast, are more vulnerable to warmth than pellets, but likewise do best anaerobic at 4 °C.

Practically, split hops into small packs, vacuum-seal or CO₂/N₂-flush, and keep them refrigerated or frozen; avoid repeated opening/resealing and minimise headspace. If you can’t guarantee low oxygen, cones may weather short-term exposure slightly better than pellets, but both formats deteriorate quickly when warm and oxygenated. Also note the quality changes: hydrocarbons such as myrcene fall fast while oxygenated terpenes can rise then decline, so “just dosing more old hops” won’t recreate fresh-hop aroma. In short: vacuum + 0–4 °C (or colder) beats everything; air + room temp ruins hops fast.

- Temperature: as close to 0–4 °C as feasible.

- Oxygen: vacuum or inert-gas flush and keep sealed; limit opens.

- Format: for long holds with proper oxygen control, pellets are efficient and stable; if oxygen ingress is likely, cones can be less vulnerable in the early months.

- Monitoring: log HSI and oil markers (e.g., myrcene, linalool) by lot over time to anticipate recipe tweaks.

2.8 One last thing… Supply chain reality check

Between farm, processor, importer and retailer, hops are usually packed in foil-laminated, vacuum-sealed or nitrogen-flushed bags and should remain at 0–4 °C. In practice you won’t see every hand-off, so brief warm stints or leaky seals do happen. Buy from outlets that visibly run a cold chain (e.g. Brouwland keeps hops in fridges at ~4 °C, visit their physical shop and you can see the dedicated fridges). When in doubt, favour suppliers who state cold-chain handling, and treat any puffy, warm, or sun-exposed packs as suspect.

A superb direct-from-farm option is ’t Hoppecruyt (Belgium). While the range is naturally limited to their cultivars, quality is exemplary: they manage the full chain in-house and get hops picked, dried, pelletised and packed within 24 hours, delivering exceptionally fresh, aromatic product with minimal oxidation and oil loss. For aroma-driven beers, that speed matters.

Please note that we have no commercial relationship with the above mentioned establishments – recommandations are independent and based on our own observations.

Home storage (best reasonable practice):

- Vacuum + barrier + cold. Use high-barrier foil bags and vacuum/heat-seal. Store 2–4 °C for near-term use or frozen (≈–18 °C) for longer holds. Pellets benefit especially from oxygen exclusion (chamber vacuum sealers are great!).

- Pre-portion on first open. Split the main bag into single-use pouches (e.g. 25–100 g). Label variety, AA %, and date to avoid repeated opens and headspace build-up. Best if you can plan your future brews ahead of time and do the split on first-open!

- Short-term convenience. For an imminent dry-hop, lower quality sealing bags in the freezer for a few days is fine.

That routine — good bags, vacuum, and cold (ideally frozen) protects both α-acids and the volatile oils you actually want in the glass, whether you buy locally from a cold-stored retailer or direct from a fast-processing farm.

3 In-beer stability: what happens after packaging?

3.1 Hydrocarbons vs oxygenates

Similarly to what we have seen in the previous section, after dry hopping, hydrocarbons (e.g., myrcene) partition to headspace and are stripped/absorbed/oxidised quickly; oxygenated terpenes (e.g., linalool, geraniol) are more soluble and persist longer. Packaging and storage temperature steer the decay curves (read further).

3.2 Temperature dominates

Across six commercial dry-hopped beers aged 10 months at 3 °C vs 20 °C, warm storage caused:

- Major losses of hop mono- & sesquiterpenes; some esters and certain alcohols/ketones behaved more variably.

- Myrcene fell ~87% at 20 °C vs ~60% at 3 °C; limonene ~80% at 20 °C vs 20% at 3 °C.

- Linalool/geraniol were better retained (even increased at 3 °C), hinting at on-going rearrangements under cold conditions.

- Hop acids showed moderate degradation at 20 °C, minimal at 3 °C; beer pH and colour increased with time; hop creep manifested in unpasteurised beers. Sensory shifted from citrus/tropical to woody/malty/spicy with warmth and time.

3.3 “scalping” in bottles vs cans

Bottles with polymeric crown-cap liners can adsorb hydrophobic hop volatiles (“scalping”), measurably depleting beer aroma over time. GC-MS of recovered liners revealed myrcene, humulene, caryophyllene and others in the liner after storage — far less so in cans, which retained these compounds better during ageing. Warmth worsened liner damage and changed which compounds persisted on the liner (and which simply disappeared).

Implications for shelf life:

- Cold chain is non-negotiable for hop-forward beers.

- Cans generally protect hop aroma better than crown-capped bottles for long distribution.

4. Conclusion

4.1 The three lives of hop aroma: stability at harvest, during storage, and in beer

- Wet hops heat and “mowburn” quickly in piles; thin layers and fast drying are essential.

- Low-temperature kilning (~40 °C) preserves ~90% of oils vs fresh; standard 55 °C kilning can cut oils by ~36–43% in the examples tested, though relative composition is largely unchanged.

- Alpha-acids and oils decline far faster at room temperature and in air; cold and anaerobic are non-negotiable. Pellets outlast cones anaerobically, but cones can outperform pellets if oxygen is present.

- HSI rises with age and heat; track it lot-by-lot as a quick health check.

- In finished beer, highly volatile hydrocarbons (e.g., myrcene) fade fastest; oxygenated terpenes (e.g., linalool) are more persistent; cold storage dramatically slows losses, and packaging liners can absorb terpene aroma.

4.2 Notes on variability according to the literature

Variety matters. Across multiple datasets, variety drove early-phase differences; after a few months, storage conditions dominated.

Totals vs ratios. Total oil can fall steeply while relative composition can shift modestly; your beer may smell similar but simply quieter.

Pellets vs cones is conditional. Pellets win when oxygen is excluded; cones can win when it isn’t. Design storage and logistics accordingly.

4.3 Survivables vs hydrocarbons

When to dose: Whirlpool/Dip Hopping and active-fermentation dry hop carry survivables better than late, static cold-side alone.

What to track: Prioritise linalool/geraniol for survivable roles; treat low myrcene as an age/abuse flag, not a goal.

After packaging: Cold storage markedly slows aroma fade; hydrocarbons collapse fastest at ambient.

5. References

- Canbaş, A., Erten, H., and Özşahin, F. (2001), The effects of storage temperature on the chemical composition of hop pellets. [10.1016/S0032-9592(01)00134-0]

- Skinner, R. N., Hildebrand, R. P., and Clarke, B. J. (1977), The effect of storage temperature on the stability of the alpha-acids content of baled hops. [10.1002/j.2050-0416.1977.tb03811x]

- Rutnik, K., Ocvirk, M., and Košir, I. J. (2022), Changes in Hop (Humulus lupulus L.) Oil Content and Composition during Long-Term Storage under Different Conditions. [10.3390/foods11193089]

- Mikyška, A., and Krofta, K. (2012), Assessment of changes in hop resins and polyphenols during long-term storage. [10.1002/jib.40]

- Rutnik, K., Ocvirk, M., and Košir, I. J. (2023), The Stability of Hop (Humulus lupulus L.) Resins during Long-Period Storage. [10.3390/plants12040936]

- Likens, S. T., and Nickerson, G. B. (1973), Factors Controlling the Storage Stability of Hops. [10.1080/00960845.1973.12006003]

- Kemp, O., Hofmann, S., Braumann, I., Jensen, S., Fenton, A., and Oladokun, O. (2021), Changes in key hop-derived compounds and their impact on perceived dry-hop flavour in beers after storage at cold and ambient temperature. [10.1002/jib.667]

- Drexler, G., Bailey, B., Schönberger, C., Gahr, A., Newman, R., Pöschl, M., and Geiger, E. (2010), The Influence of Hop Harvest Date on Flavor Stability in Dry-hopped Beers. [10.1094/TQ-47-1-0219-01]

- Rybka, A., Krofta, K., Heřmánek, P., Honzík, I., and Pokorný, J. (2018), Effect of drying temperature on the content and composition of hop oils. [10.17221/482/2018-PSE]

- Nickerson, G. B., and Likens, S. T. (1979), Hop Storage Index. [10.1094/ASBCJ-37-0184]

- Monacci, E., Sanmartin, C., Bianchi, A., Pettinelli, S., Najar, B., Mencarelli, F., and Taglieri, I. (2025), Chemical Quality and Characterization of Essential Oils in Postharvest Hop cv. Cascade: Ventilated Room Temperature as a Sustainable Alternative to Hot-Stove and Freeze-Drying Processes. [10.3390/beverages11020054]

Recent Comments